Manure Compost, Jumpstart your compost, Hastens the composting time

Guangming dairy farm located in west region of Shenzhen, breeded 3500 cows, and these cows generate a lot of manure (approximately 210 ton per day). Currently they store a significant portion of their in lagoons and then apply the manure in liquid form onto their fields to fertlize the crops they grow for cow feed. While dairies that produce more manure nutrients than required to grow their feed crops face a serious challenge in how to mange their excess manure.

After site evalulation, Tangsons Biotech Team proposal for composting dariy manure, it offers an alternative to manure over-application by increasing the land base over which the manure nutrients can be applied. Composting kills pathogens and converts manure into a lighter, more nutrient-dense form. The pathogen kill enables manure compost to be applied to human-consumed crops on the dairy itself, and the lighter material is more easily transported further from the dairy, enabling better distribution of nutrients as compared to uncomposted manure. With Microbiological technology, Tangsons compost inoculant is made up of bacteria and fungi that encourage decomposition, so it can jumpstart the compost and hasten the compost time, and curbs the emission of foul odour.

First, seek out a level, well-drained area. In wet and cooler regions, you will want to store your compost pile in a sunny spot. This will allow you to trap in solar heat (for during the colder months of the year). In warmer, drier areas, store your compost pile in a shaded spot so the pile does not dry out too quickly.

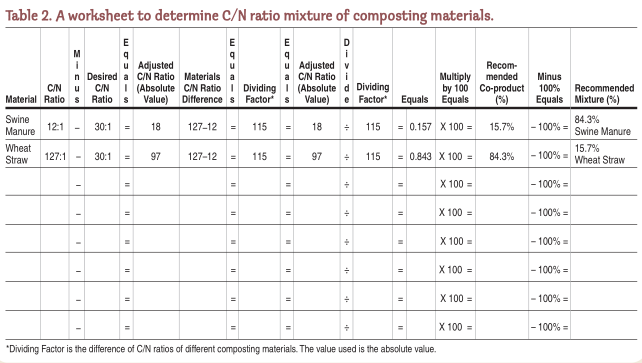

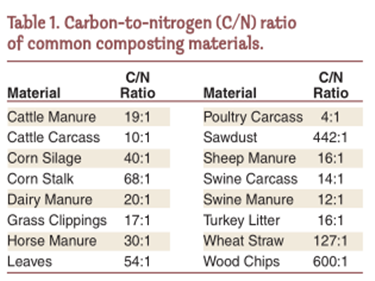

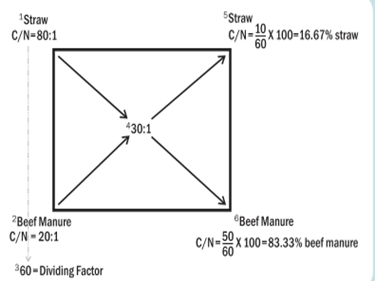

The carbon to nitrogen (C/N) ratio in a composting pile needs to range from 20-to-1 (20 parts of carbon for every part of nitrogen) to 40-to-1 (40 parts of carbon for every part of nitrogen). Decomposing microorganisms typically have a C/N ratio of 5-to-1 to 10-to-1. The C/N ratio needs to be higher because approximately 50 percent of the metabolized carbon is released as carbon dioxide. Nitrogen can be lost when too much (C/N ratio below 20-to-1) is present, and the pile might smell of volatizing ammonia. Adding carbon (straw or woodchips) can help alleviate this. Too much carbon (C/N ratio more than 40-to-1) in a compost pile can immobilize nitrogen and slows the composting process.

While Composting material's C/N ratio varies greatly, The C/N ratio of bulking materials of plant origin varies greatly as well and for the same reasons as manures. The Following table outlines many of the properties that various composting materials possess.

Compost piles that are about 1 cubic yard (3 ft square by 3 ft high) get hotter quicker. (Up to 140 degrees F!) Heat is a by-product of rapid microbial action and a sure sign that the microbes are working at top speed to break down the materials. Smaller piles and larger piles don't heat up as quickly.

Compost inoculant are also called compost accelerators or compost boosters and compost starters. This is natural material that break down plant matter and speeds up the natural decomposition processes taking place in your compost , When you haven't got a lot of time to wait for compost to happen naturally, so it is time to inoculante composting microbes.

Tangsons Biotech Composting microbes is made up of minerals and microbes that encourage decomposition, so it can jumpstart your compost and quick rise the compost temperapture as required.

Water is another key component in making compost, but you don't need too much, because 40 to 65 percent of the pore space in compostingmaterials should have water. Measuring devices can be used to monitor the moisture, but they can be costly.A good rule of thumb is to leave your compost as damp as a wrung-out sponge. when you hold in hand, it will become a ball, when fell into ground from 1 meter high, it will be dispersed as following

One of the easiest and most natural ways to accelerate composting is to cover the pile with a film. There are many reasons why this is helpful. Rainwater cools down the compost, which slows down the decomposition process. When the water runs off the pile, it can also leach away valuable and needed microbes and minerals. This will also slow down the composting process.

Cover your compost to keep the environment warm and to keep it controlled. You'll lose less from the pile, and that means it will have more to work with as it decomposes over time.

Decomposition occurs most rapidly between 104-131 degrees Fahrenheit. Aerating and turning should only occur when the temperature slips below 104 degrees. Should you choose to go the active composting route, you can purchase a compost thermometer that will help you gauge the ‘peak’ times of your pile.

Organic operations must meet certain temperature and turning frequency requirements. It requires pile temperatures to exceed 131 F for 15 days and piles to be turned atleast five times. If Piles exceed 160 F, which can destroy the benefi cial microbes, causing a decline in microbial activity and slowing the process. If this occurs, chances are the piles have too much nitrogen. Adding carbon, making the piles smaller and digging holes in the pile are ways of cooling the pile.

Turning manure is essential to composting manure. Turning compost incorporates oxygen into the system, homogenizes the pile and breaks up clumps. Mixing allows more contact of manure with microbes. Turning the materials in your pile once a week will add the needed air. If you can't—or don't want to—turn the pile, try aerating it by poking around in the pile with a pitchfork.

Producers have various ways to turn the pile. The two most common methods for turning compost are with a windrow turner or bucket tractor. Turners may be self-propelled or attached to a tractor or skid steer. Turners mix the compost by an auger, rotary drum with flails or an elevating conveyor. Some turners require power from the attached implement, while others are self-powered.

To evaluate the matutity of compost, The finished compost is dark brown, crumbly and earthy-smelling. Be sure that your finished product is completely decomposed and thus, is ready for use. If you notice small pieces or leaves in the pile, these are partially decomposed remnants and should be used as a mulch. Do not use them as fertilizer as it will deprive your plants of nitrogen. Nitrogen is essential to the growth of plants nearby. A smart move would be to sort out those items not yet decomposed and leave them for the next batch of compost.

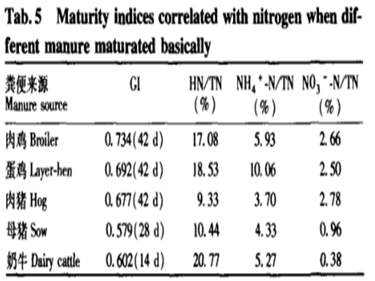

Moreover, According to the comprehensive evaluation index GI value meets the standard of maturity requirements (GI>0.50), except for piglet manure, other livestock and poultry manure are in HN/TN<20.77%, NH4+-N/TN<10.06% and NO3-N When /TN>0.38%, the maturity requirement is basically reached.