Swine Farm Wastewater Treatment

1) Project: XiangYang Piggery farm with 300 m3/ day

2) Wastewater type: Poultry wastewater (Piggery farm)

3) Project problem: Biogas slurry odor problem, Biological system malfunction

4) Flow Diagram: Influent > EQ > Solid liquid separation > clarify tank #1 > Clarify tank #2

> Clarify Tank 3 > Anoxic tank > Aeration tank > 2nd sediment tank > Effluent > Irrigation

5) Tank Size: Biogas slurry tank 14,000 m3, Clarify tank 15,000 m3, Anoxic tank 100 m3, Aeration 600 m3

1) Biogas slurry tank problem and retrofit suggestion:

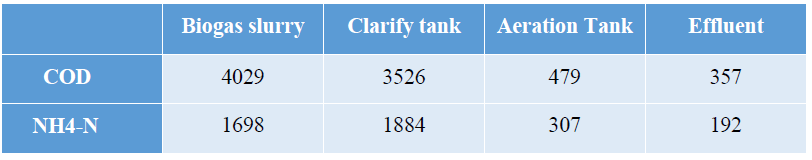

Biogas slurry tank has high suspended solids and black residue, which contains high COD level and make shock load for biological system. Suggest to regularly cleaning to avoid black residue flow into clarify tank.

2) Clarify tank problem and retrofit suggestion:

3 clarify tank, each 500 m3, HRT 5 days, since no any aeration equipment, so it is used as anoxic storage tank, As indicated in above wastewater analysis chart, COD & ammonia reduction performance is very low.

. For clarify tank #1, suggest inoculating ODOR CONTROL that is help to odor elimination and reduce COD and ammonia level, decreasing shock load for following treatment.

. For clarify tank #2, suggest installing 2 unit aerators, and dosing ODOR CONTROL iii) For clarify tank #3,

Suggest installing jet aerator, and inoculate Aerobic Bacteria + NITRIFYING BACTERIA to reduce COD & ammonia. Meanwhile, backflow

from clarify tank #3 to #2.

3) A/O system problem and retrofit suggestion:

Anoxic tank 100 m3, aeration tank 600 m3, but Anoxic is no any activated sludge already due to no any sludge backflow & submersible mixer. Suggest back flowing sludge to anoxic tank, and inoculating ANAEROBIC DIGEST + DENITRIFYING to cultivate bacteria. Inoculate Aerobic Bacteria + NITRIFYING BACTERIA to aeration tank to reduce COD & ammonia.

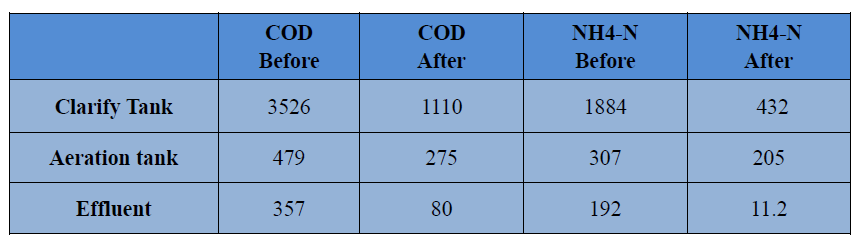

Before Retrofit

Before Retrofit After Retrofit

After Retrofit1) Daily seeding 10 kg Odor control for clarify tank #1 & #2 each to eliminate odor for 15 days,

2) Daily seeding 6.5 kg Nitrifying bacteria + aerobic bacteria respectively to clarify tank #3 for 15 days,

3) Daily seeding 2 kg ANAEROBIC DIGEST + 2 kg denitrifying bacteria to anoxic tank for 15 days,

4) Daily seeding 8kg Aerobic Bacteria + nitrifying bacteria each to aeration tank for 15 days,

1) Odor completely controled in biogas slurry tank

2) After cultivate bacteria for biological system, the activated sludge improved significantly in anoxic tank

3) COD reduced from 3526 to 80 mg/L, Ammonia reduced from 1884 to 11.2 mg/L

4) Consistently meet irrigation regulation.